OUR MOVE

How could machine learning cut costs and save time?

Cost is a constant factor that lurks in businesses — from manpower to the smallest of expenses, and even unforeseeable events that hinder a business’ activities.

The question is — what role does machine learning play in cutting costs?

As we learn in this present time, with the most up-to-date technology, artificial intelligence-derived learning is the way forward where information and data are computed, complemented by the right commands and complex algorithm sets, to deliver the most efficient approach to achieving results.

That in itself is the first step to reducing long-term costs, deviating from human resources to a computer-based tool. Although a pricey investment in the initial stage, this could prove to be a business-sustaining alternative in the long run when it comes to trimming costs.

Oil and gas refinery and production plants are certainly no stranger to encountering various levels of costs which spawn on a daily basis. One of many critical expenses to be introduced in this field is derived from unplanned errors which could be attributed to a result of a machine breakdown — costing millions in replacing damaged parts and time loss in yielding profit.

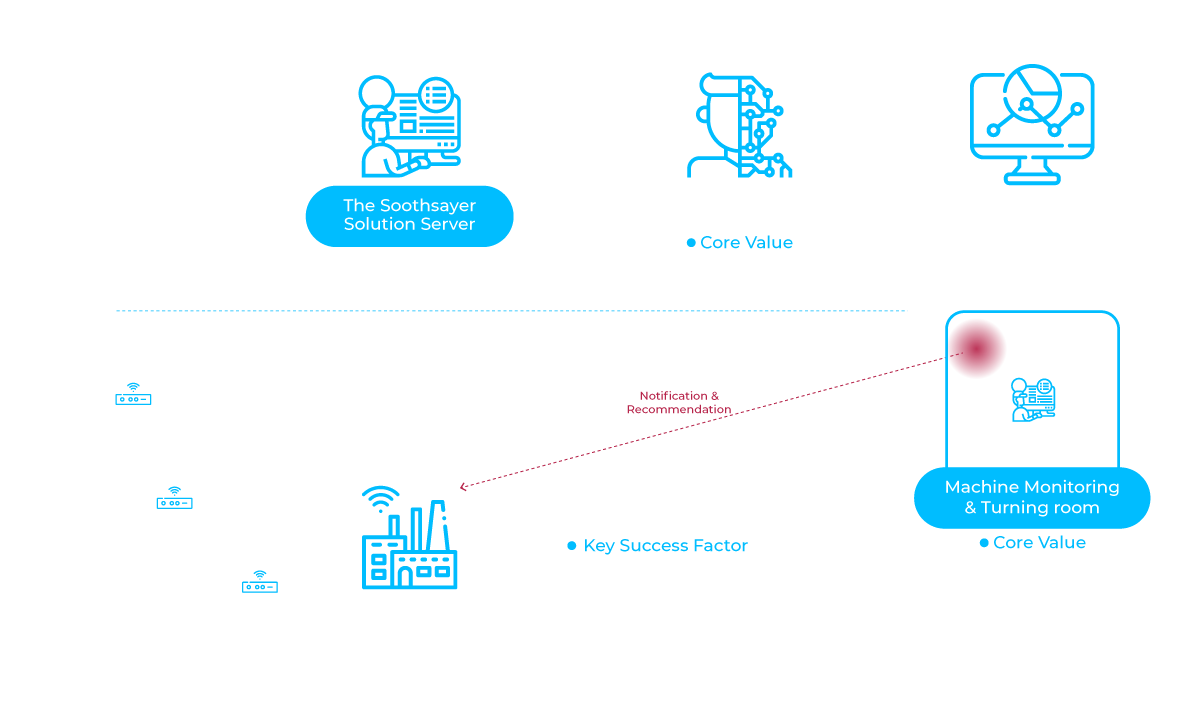

By suitably applying machine learning maintenance, or statistics analytics level of maintenance [hyperlink to The Soothsayer ‘Product Features’ page for SEO] which happens to be significantly more advanced, to operating systems that require an elite-level maintenance, key precautions are taken.

First, data provided from physical sensors, wherever they are installed, can help the algorithm identify what is considered to be ‘normal’ from anomalous behavior. This, in turn, should notify the software engineers of any potential occurrences that may lead to malfunctions, and worst case scenario, severe machine breakdown — before they actually happen. This act of safeguarding machines and essential operational tools is cost-saving.

The possibility of avoiding risks which obstruct the opportunity to yield profit, thanks to the predictive learning of statistics analytics maintenance, is not only a safer bet to consider but one which is an improvement from traditional approaches to maintenance — from corrective maintenance, to time-based maintenance, and performance monitoring which require more human oversight and spare part replacement; both of which can be avoided.

LOGO-P-DICTOR(COLOR).png)